- Home

- Brand

- Laser Power

- Marking Size

- Marking Speed

- 0- 10000mm / S (155)

- 0-12000mm / S (3)

- 0-7000mm / S (11)

- 0-8000mm / S (78)

- 12m / S (3)

- 15000 Mm / S (3)

- 15000mm / S (149)

- 1500mm / S (2)

- 2m / S (2)

- 6000mm / S (6)

- 7000 Mm / S (67)

- 7000mm / S (114)

- 7m / S (23)

- 7m / S (275.6in / S) (45)

- 7m / S275.6in / S (4)

- 8000 Mm / S (65)

- 8000mm / S (6)

- Up To 10000mm / S (13)

- Up To 7000mm / S (2)

- ≤7000mm / S (8)

- ... (3634)

- Software

- Voltage

- 110 / 220v (128)

- 110 V (3)

- 110 V, 60 Hz (103)

- 110v (65)

- 110v / 220v (90)

- 110v / 220v Optional (3)

- 110v 60hz (78)

- 110v, 50 Hz (3)

- 110v, 50hz (4)

- 110v, 60 Hz (38)

- 110v, 60hz (10)

- 120v 60hz (5)

- 220v (13)

- 220v / 110v (2)

- 220v, 50 Hz (9)

- 220v, 60 Hz (6)

- Ac 110 / 220v (5)

- Ac 110 V (7)

- Ac 110v (3)

- Ac220 / 50hz (12)

- ... (3806)

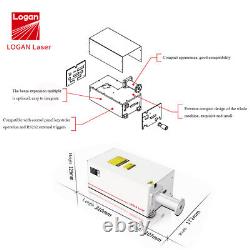

Logan 5W UV Laser Fiber Laser Engraving Marking Machine Glass Leather Plastic

America Business ALL ITEMS IN STOCK IN AMERICA. AMERICA STANDARD PRODUCTS QUALITY GUARANTEED. Logan 5W UV Laser Fiber Laser Engraving Marking Machine Glass Leather Plastic. Item was as described and arrived quickly. The ultraviolet laser marking machine quicks turnaround and perfect accuracy.

Our device's state-of-the-art air-cooled logan uv laser avoids the tetchiness, fragility, and water-based mess of CO2 laser tubes. Instead, it provides solid-state efficiency, quality, stability, and durability for its entire service life of 100,000 hours.

The Galvo galvanometric system and compact F? Field lens ensure quick work with less than 1% distortion from your design. The built-in red dot locators allow you to precisely adjust the height of the laser arm to quickly find the exact focus for various materials. The machine is controlled by its included copy of EzCad2.A pair of laser glasses come included to protect your eyes from the 355nm beam of this laser. Advantages of UV Laser Marking M achi ne. Ultra-fine marking and marking of special materials possible. Due to the extremely small focus and small processing heat-affected zone, UV laser can carry out ultra-fine marking and special material marking.

It is the first choice for customers who have higher requirements on marking effect. Cold processing method with better effect. Ultraviolet laser processing has become cold processing, because the high-energy molecules of the ultraviolet light will need to be processed directly to the separation of molecules on the metal or non-metallic materials. However, this separation causes the molecules to separate from the material. No heat is generated in this mode of operation.

On the basis of cold processing, the results of processing products and materials will be better and better. This is because when cold laser processing is used, the probability of material impact is reduced to one percent, which reduces the advantages of processing. The heat affected area of UV laser marking machine is extremely small, which will not produce thermal effect and will not cause the problem of material burning. UV laser is mainly low power, stable performance, small size and low power consumption.UV laser marking machine: especially suitable for the high-end market of fine processing. Cosmetics, pharmaceuticals, excipients and other polymer materials such as packaging bottle surface marking effect, strong cleaning force, better than inkjet coding, no pollution.

Flexible pcb board marking and scribing; silicon wafer microporous, blind hole processing. LCD liquid crystal glass two-dimensional code marking, glassware surface drilling, metal surface coating marking, plastic buttons, electronic components, gifts, communication equipment, building materials and so on. Certified compliant with ISO standards 11553 & 12100 and IEC standards 60204 & 60825, this fiber. Machine lets you produce professional quality engravings with depen.

Compare to traditional fiber laser, it Mainly uses non-metallic materials as the object of surface marking such as: glass, plastic bags, paper packaging boxes, etc. Visible laser pointers help make focusing quick and easy. The built-in red laser locator calibrates with the laser's scanner to allow precision work on the machine's workbed and make a preview for your pattern's outline for convenient positioning. Software Support - Your UV fiber laser comes with a bundled edition of.

Engraving software compatible with Windows. Users can design their graphics freely, common types of images are supported. Bmp, jpg, tga, png, tif... , common vector images are supported.Lens helps create vivid markings on flat surfaces, maintaining a consistent, focused spot size across its. Producing less than 1% distortion, it flawlessly executes intricate designs with unbelievable precision. LightBurn Compatible - Your EzCad2-based ultraviolet laser engraver works with. S latest galvo functionality on.

Windows, MacOS, and Linux systems. To let you create even the most intricate patterns easily. The text information marked by the uv laser marking machine is clear and permanent, and will not fade and fall off.The beam quality is high, its diameter is 0.6-0.9mm, and the divergence angle is <2mrad. Waste heavy water cooling unit, small footprint, more convenient installation, truly energy-saving, portable. High electro-optic conversion efficiency, easy to use, no optical adjustment or maintenance, compact structure, high system integration and low failure. No maintenance, long service life, suitable for harsh environments.

Fast processing speed, 2-3 times that of traditional marking machine, optical scanning galvanometer, high laser repetition frequency, high speed and no distortion. The equipment is applicable to the surface and internal carving of. Marking and carving of high flame retardant materials and other surface treatment, and at the same time, it can be applied to the surface processing of most of the. And the processing of coated films, which belongs to a kind of high-grade fine marking of the special equipment. Your kind consideration is highly appreciated.

If you do not like the goods and would like to return them to us, please see below. Before returning the goods to us, please tell us first. Please return the goods to us within 7 days after you have received the goods. Please confirm the goods as original packing. Ut please do not forget to send us some clear photos. We offer detailed product descriptions and images to give you a real advantage in finding the products you're looking for. We have a highly experienced engineering and technical team who specialise in researching and developing all our products. We benchmark our products against high standards and that's why our customers keep coming back. After you have ordered, you must pay within 7 days.