- Home

- Laser Frequency

- Laser Power

- Marking Size

- Marking Speed

- 0- 10000mm / S (155)

- 0-12000mm / S (2)

- 0-7000mm / S (11)

- 0-8000mm / S (59)

- 12m / S (3)

- 15000 Mm / S (3)

- 15000mm / S (146)

- 1500mm / S (2)

- 6000mm / S (2)

- 7000 Mm / S (67)

- 7000mm / S (114)

- 7m / S (23)

- 7m / S (275.6in / S) (45)

- 7m / S(275.6in / S) (2)

- 7m / S275.6in / S (4)

- 8000 Mm / S (63)

- 8000mm / S (6)

- Up To 10000mm / S (13)

- Up To 7000mm / S (2)

- ≤7000mm / S (8)

- ... (3573)

- Software

- Voltage

- 110 / 220v (128)

- 110 V (2)

- 110 V, 60 Hz (101)

- 110v (48)

- 110v / 220v (86)

- 110v / 220v Optional (3)

- 110v 60hz (74)

- 110v, 50 Hz (3)

- 110v, 50hz (2)

- 110v, 60 Hz (32)

- 110v, 60hz (10)

- 120v 60hz (5)

- 220v (12)

- 220v, 50 Hz (8)

- 220v, 60 Hz (3)

- Ac 110 / 220v (5)

- Ac 110 V (7)

- Ac 110v (3)

- Ac 110v / 220v (2)

- Ac220 / 50hz (11)

- ... (3758)

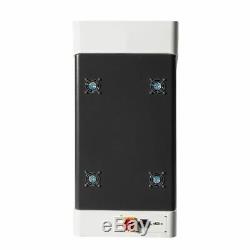

Q-P Closed Fiber Laser Marking Machine Supports Automatic Focus

Q-P Closed Fiber Laser Marking Machine Supports Automatic Focus. Bmp, jpg, gif, tga, tif, at dxf, dst, plt, etc. Marking format graphics, text numbers, bar codes two-dimensional code, real-time, batch number etc.

This series of products adopt European standard , the first self-developed auto focus function, which can automatically detect the thickness and automatically calibrate. One Button To Intelligent Marking Automatic Focal Length Control European Standard Of Protection Beautiful Appearance And Reliable Quality Features: 1. Automatic focus control Machine can detect the thickness of the workpiece automatically. We are the first company in China applied this technology in laser marking machine.

Automatic door the door will be automatic lifting down before work start and lifting up when finishing marking. Laser source will be automatic cut off once the door is opened while machine working. European standard of protection: DO+4. Beautiful appearance and reliable quality. Flexible variable text: Changes the text real time while in laser processing. Image processing (Gray scale, White / Black Transformations); 8. More convenient IO operations make it easier to harmonize the auxiliary equipment. An opening language supporting system makes it easier to run the software in various Languages platform. Details: Suitable for electronic components, integrated circuits, electrical appliances, communication products, sanitary ware, tools, accessories, knives, glasses, clocks, jewelry, auto parts, luggage buckles, kitchen utensils, stainless steel products and other industry products, etc.For artistic, clear and permanent identification mark. The PC included marking machine is only for picutures with 10 inch display screen.

Aluminum Aluminum is one of the most commonly marked substrates, and we use it in many industries. Typically, with lighter marking intensity, aluminum will turn white. Anodized aluminum looks good , but white marking is not ideal for bare and cast aluminum. More intense laser settings provide a dark grey or charcoal color.

Each DLM fiber laser engraving machine is capable for aluminum marking. The ideal system for your application depends on your laser marking requirements. Ablation is the most common marking technique for anodized aluminum, but some people call for etching or engraving. Brass and copper Brass and copper have high thermal conductivity and thermal transfer properties.

So we use it for wiring, printed circuit boards and pressurized flow meters. Their thermal properties are ideal for laser marking systems for metal because the heat is quickly dissipated. This reduces the impact the laser can have on the structural integrity of the material. Every DLM fiber laser engraving machine is capable of marking on brass and copper and the ideal system for your application depends on your marking requirements. The best marking technique depends on the finish of the brass or copper.

Smooth surfaces can offer a soft polished marking affect, but also can do annealed, etched, or engraved. Etching or engraving is best in order to provide readability by humans and machines. In some cases a dark anneal can work, but surface irregularities can cause reduced readability. Tungsten and Carbide Tungsten and Carbide are two of the hardest metals on earth and are widely used in tooling and cutting applications. Another popular segment for these substrates is wedding bands for men.

Tungsten and carbide are receptive laser marking metals and laser engraving metals. Each and every DLM Laser series is capable of marking on tungsten and carbide and the ideal system for your application depends on your marking requirements. For carbide, because of the darker color it naturally has, getting a contrasting mark is rather easy with even light laser intensity.

A white color is most common when polishing or annealing carbide and the contrast is extremely good. Chrome Chrome plating provides a stylish and sophisticated finish, and usually requires minimal laser intensity to remove or get through the plating. We need take ensure the marking happens on the surface only, with no impact to the chrome plating. 606mm x 350mm x 670mm (24in x 13.8in x 26.4in). 550mm x 800mm x 900mm (21.7in x 31.5in x 35.4in).The item "Q-P Closed Fiber Laser Marking Machine Supports Automatic Focus" is in sale since Monday, June 10, 2019. This item is in the category "Business & Industrial\Printing & Graphic Arts\Screen & Specialty Printing\Engraving". The seller is "laserfactory2016" and is located in Beijing. This item can be shipped worldwide.

- Model: LMM-AQ-FM-P

- Country/Region of Manufacture: China

- Engraving Method: Laser

- MPN: 0116002761300

- Power: 20W / 30W / 50Woptional

- Brand: QOMOLANGMA

- Supported formats: bmp, jpg, gif, tga, tif, at dxf, dst, plt, etc.